|

|

|

Differences between ESD and EOS |

Both ESD (Electro Static Discharge) and EOS (Electrical

Over Stress) are related types of voltage overstress. The

clear difference is that ESD is a very high voltage (>500V)

with relatively short duration (<1μsec) whereas EOS is

a moderate voltage (<100V) with longer time span (normally>1μsec).

Richtek IC ESD cells are designed to survive the energy

of an ESD pulse based on Human Body Model (HBM) or CDM (Charged

Device Model), which are well quantified and represent a

certain energy surge in the ESD cell. EOS events are longer

duration events, and the energy surge during EOS can easily

exceed the levels of ESD events.

.png) |

|

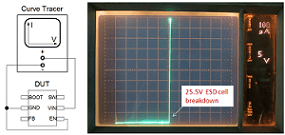

Measuring ESD cell characteristics |

To see the point where IC failure starts to happen, you

can measure the actual ESD breakdown voltage, either via

a curve tracer or by applying a pulsed current to the device

under test, which is a more precise measurement

to check the actual ESD cell failure point. The ESD cell

maximum surge energy can be calculated from these measurements.

.png) |

|

|

|

|

The Buck converter

RT7285C VIN ESD cell breakdown lies around 25.5V, and

rises sharply without snap-back. |

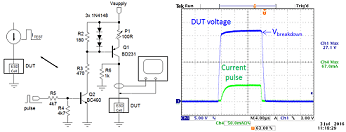

A simple switched current source with adjustable current

and pulse width can show the ESD cell breakdown and by increasing

the current the failure point can be captured. |

|

|

|

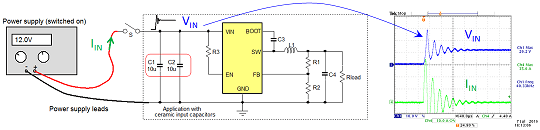

Common reasons for VIN EOS: Supply hot-plug |

|

One of the most common reasons for power IC VIN EOS is power supply hot-plug

events. Appliances that run from wall adapters with DC jacks should

always consider hot-plug events. In the lab it is easy to duplicate

the hot plug event by connecting live power supply leads to an application

which has low ESR ceramic input capacitors. The amplitude of the

voltage spike depends on several parameters like cable wire type

and length, supply impedance, input capacitor ESR and the MLCC DC

bias effect. .png) |

There are several ways to reduce the voltage ringing amplitude during

hot-plug : You can increase the output impedance of the switch-mode adapter input supply, you can increase the adapter cable resistance

or improve the coupling between positive and negative wires. Another

solution is to add an RC snubber at the converter input. For more

details on these solutions

.png) |

|

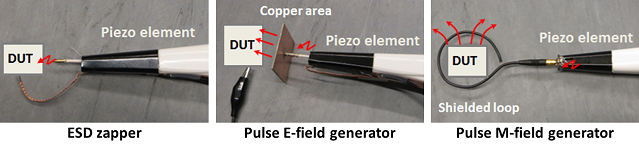

DIY tools for generating EOS |

|

|

Read here how to build these handy tools for stress testing your design on EOS. |

Breakdown characteristics of different ESD cell types

Other causes for power IC VIN EOS and their solutions |

For more details, please download the full application note

“Analysing

VIN Overstress in Power ICs” |

|

Feature Product |

|

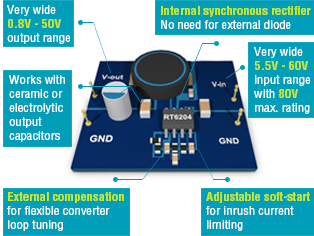

RT6204 - Richtek’s latest addition to the wide VIN converter range |

|

|

RT6204 is a Synchronous Buck converter

with a wide input range of 5.5V to 60V and

an output range adjustable from 0.8V to 50V

with 500mA current capability.

It

switches at 350kHz and is housed in a

SOP-8 thermally effective package.

The wide input range in combination with high step down

capability makes it suitable for virtually any industrial

application range, from battery fed automotive to 12V/24V/48V industrial

supplies. |

|

Featuring PSM mode for enhanced light load efficiency, RT6204 uses

current mode topology with external compensation, allowing great

flexibility in loop tuning using either ceramic or electrolytic

output capacitors. The 80V max rating makes this IC very tolerant

to hot-swapping and other supply voltage transients. Slew rate limited

switching helps to reduce EMI radiation.

Applications: automotive

electronics, solar power systems, networking and telecommunication

systems, industrial and communication low power systems, LCD monitors

and TVs, LED lighting, motor drive bias supply, etc.

Please contact our sales offices for samples to get your design started in no time. |

|

New Products |

|

RT9072A/B is a wide 4.5V to 80V

input, wide 1.25V to 60V output, 20mA Low dropout voltage

Linear Regulator in SOT-23-5 package. -80V reverse-battery

protection, ±3% output tolerance over line, load &

temperature range and low quiescent current make it a robust

solution for powering sensors or MCUs in battery-powered

applications, telecom and Datacom, automotive applications,

etc. |

|

RT4805 is 1.8V to 5V input, 2.85V to 4.4V

output, up to 2A, 2.5MHz, synchronous Boost converters with

Bypass Mode in WL-CSP-16B 1.67x1.67 package in

I2C

controlled interface. Built-in power transistors, ultra-low

operating quiescent current and smooth transitions between

bypass mode and boost mode or forced low Iq bypass mode

makes it suitable for battery powered wearables,

sensors, smartphones and tablets, 2.5G/3G/4G mini-module

data cards. |

|

RT6216 /

RT6217 ACOT® Synchronous Buck Converters family

are 4.5V to 23V input, 2.5A/3A

output current, 500kHz or 800kHz for options, in compact

TSOT-23-8 packages. The ACOT topology provides

ultra-fast transient response, and a constant switching

frequency, ideal for Set Top Box, portable TV, access point

router, DSL modern and LCD TV powered from 5V, 12V or 19V

supplies.

Also see other ACOT® products |

|

| |

|